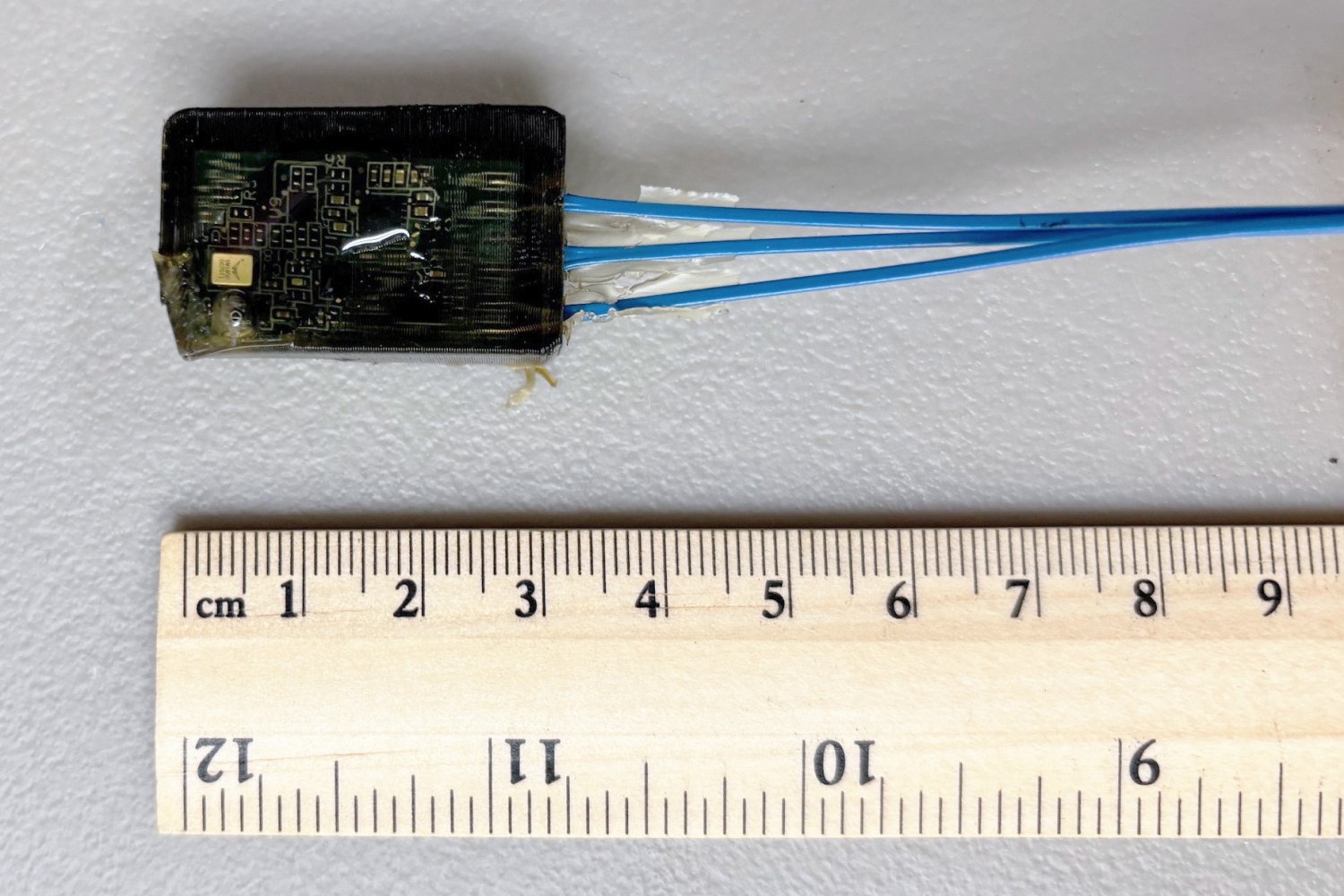

With funding from the Office of the Under Secretary of War for Research and Engineering to develop a novel hydrophone, the team first planned to use microfabrication, an area of expertise at the laboratory, to develop their device. In collaboration with researchers at Tufts University, as well as industry partners SeaLandAire Technologies and Navmar Applied Sciences Corp., the team made the hydrophone by encapsulating the MEMS microphone in a polymer with low permeability to water while leaving an air cavity around the microphone’s diaphragm (the component of the microphone that vibrates in response to sound waves). After a substantial amount of simulation, design iterations, and testing, the team found that the signal lost from incorporating air into the device was compensated for by the very high sensitivity of the MEMS microphone itself.

Author: Nathan Parde | MIT Lincoln Laboratory

Published at: 2025-11-17 22:00:00

Still want to read the full version? Full article